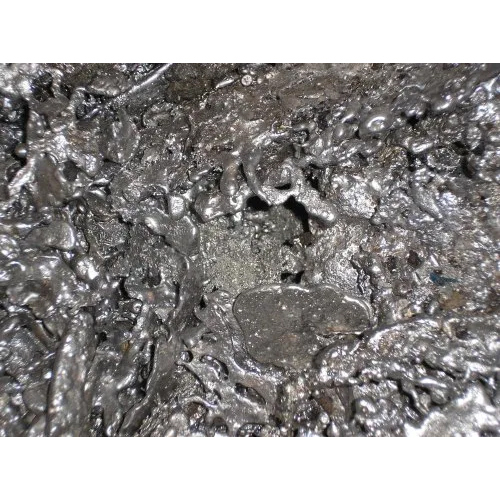

Tin Alloy

2700 आईएनआर/Kilograms

उत्पाद विवरण:

- शर्त New

- ग्रेड Reagent Grade

- पवित्रता 98%

- रचना Tin with antimony, copper, or bismuth.

- रंग Sliver

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 100

उत्पाद की विशेषताएं

- Tin with antimony, copper, or bismuth.

- New

- 98%

- Reagent Grade

- Sliver

व्यापार सूचना

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

उत्पाद वर्णन

Tin alloys are metallic materials made by combining tin (Sn) with one or more other metals to enhance their physical, chemical, and mechanical properties. Tin serves as the primary component in these alloys, contributing to their excellent corrosion resistance, low melting points, and ease of workability.

Common Tin Alloys and Their Applications

-

Solder Alloys

- Composition: Tin combined with lead, silver, or copper.

- Properties: Low melting point, good wettability, excellent conductivity.

- Applications: Used in electronics for joining components, plumbing, and electrical work.

-

Bronze

- Composition: Tin and copper (with possible small amounts of phosphorus, aluminum, or silicon).

- Properties: High corrosion resistance, good strength, and ductility.

- Applications: Bearings, coins, sculptures, and marine applications.

-

Pewter

- Composition: Tin with antimony, copper, or bismuth.

- Properties: Low melting point, malleable, and bright silvery finish.

- Applications: Tableware, decorative items, and jewelry.

-

Bearing Alloys (Babbitt Metals)

- Composition: Tin, lead, antimony, and copper.

- Properties: High wear resistance and low friction.

- Applications: Used as a lining for bearings in machinery.

-

Tin-Zinc Alloys

- Composition: Tin and zinc.

- Properties: Excellent corrosion resistance.

- Applications: Used for coatings in automotive and industrial sectors.

-

Tin-Lead Alloys

- Composition: Tin and lead in various ratios.

- Properties: Soft, corrosion-resistant, low melting point.

- Applications: Roofing materials, battery grids, and cable sheathing.

Key Properties of Tin Alloys

- Corrosion Resistance: Tin provides excellent protection against oxidation and corrosion.

- Low Melting Point: Ideal for applications like soldering.

- Malleability and Ductility: Easily shaped for diverse uses.

- Good Electrical and Thermal Conductivity: Suitable for electronic and industrial applications.

Environmental Considerations

- Recycling: Tin alloys are often recyclable, particularly solder alloys, to reduce waste.

- Toxicity: Lead-based tin alloys may pose environmental and health concerns, leading to a preference for lead-free alternatives in modern applications.

Tin alloys are valued for their versatility and are critical in industries ranging from electronics to art and construction.

Versatile Applications

Tin Alloy (98% purity, reagent grade) is suitable for electronics soldering, laboratory research, and metal fabrication thanks to its excellent conductivity and anti-corrosive properties. Its silver color and high-grade composition allow for precise and reliable performance across various sectors demanding quality alloys.

Superior Manufacturing Standards

This tin alloy is produced and supplied under stringent quality controls by leading manufacturers, exporters, and traders in India. Each batch maintains consistent purity and composition, ensuring reliability and uniformity for scientific and industrial use. Rigorous testing ensures it meets reagent-grade standards for demanding processes.

FAQs of Tin Alloy:

Q: How is Tin Alloy with 98% purity manufactured in India?

A: Tin Alloy with 98% purity is manufactured by blending high-quality tin with controlled amounts of antimony, copper, or bismuth in specialized facilities. Advanced refining and alloying processes ensure reagent-grade quality and uniform silver coloration suitable for precise industrial and research applications.Q: What are the main uses of reagent-grade Tin Alloy?

A: Reagent-grade Tin Alloy is commonly used in electronics soldering, chemical reactions, laboratory experiments, and certain metalworking tasks. Its composition provides enhanced strength, conductivity, and resistance to corrosion, making it effective in settings requiring high purity and dependable performance.Q: When should I choose Tin Alloy over pure tin for my application?

A: Tin Alloy is preferable over pure tin when your project demands improved mechanical strength, better corrosion resistance, and specialized properties provided by alloying elements like antimony, copper, or bismuth. Reagent-grade alloys are especially useful for laboratories and technical manufacturing.Q: Where can Tin Alloy with 98% purity be procured in India?

A: You can source Tin Alloy (98% purity, reagent grade) through trusted manufacturers, exporters, suppliers, and traders located throughout India. These providers maintain consistent inventory and can deliver alloys tailored for industrial, laboratory, or research needs.Q: What benefits does Tin Alloy offer compared to other metal alloys?

A: Tin Alloy offers excellent conductivity, strong anti-corrosive properties, and enhanced strength due to the addition of antimony, copper, or bismuth. Its reagent-grade purity makes it ideal for high-precision uses and reliable in sensitive chemical or electrical environments.Q: How is the quality of Tin Alloy ensured during production?

A: Manufacturers in India uphold stringent quality standards for Tin Alloy production by employing controlled refining, testing for purity, and strict batch consistency. Only alloys meeting reagent-grade specifications and verified composition are approved for supply and export.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

टिन स्क्रैप अन्य उत्पाद

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese